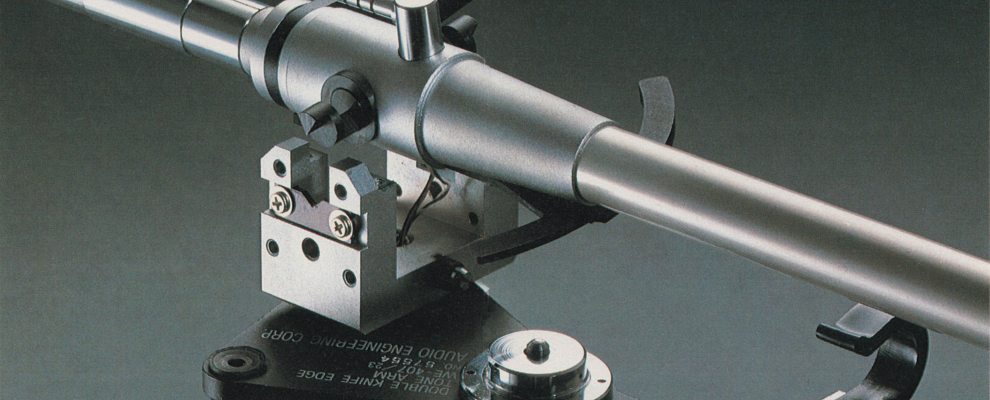

FONOLAB WE-407 TONEARMS

and Double Knife Edge technology by Sound of Audio Engineering Company (SAEC)

In this article we present the description and principle of the SAEC tonearm Double Knife Edge bearing assembly operation. We use only SAEC official figures and information.

The first time that Double Knife Edge bearing assembly was introduced was in the Model WE-308 tonearm. The development of this innovative, and as yet unsurpassed pivoting system, is the key to the truly superior performance of all SAEC tonearms. The two factors which most affect the performance of any turntable system are pivotal friction and excessive vibration. The Double Knife Edge system is so finely-machined, it produces virtually friction-free pivoting while eliminating vibration in the tonearm.

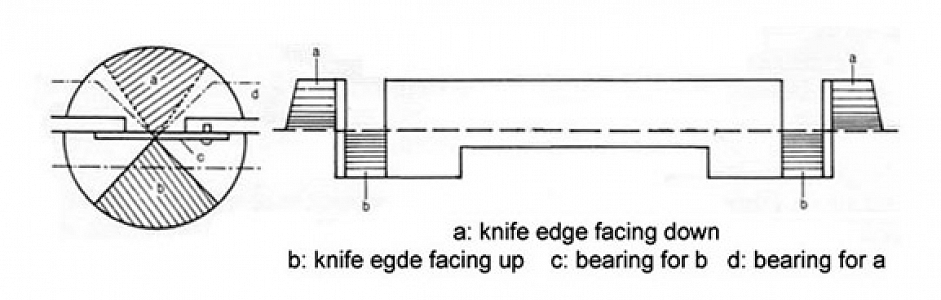

Obviously, for any bearing assembly to produce friction-free performance, is that its surface or contact-area must be small. Yet, vibration-free operation usually demands a greater contact- area. The radical design of the SAEC Double Knife Edge bearing relies on precision, hand-finished pivot-points which measure a mere 0.02 millimeters thick!

One further benefit of the Double Knife Edge system is the ability to utilize increased stylus-pressure (weight) without increasing friction. This results in better overall signal-recovery and reduced distortion.

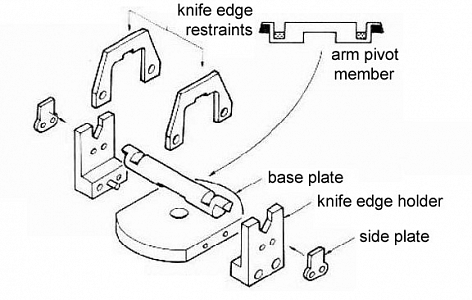

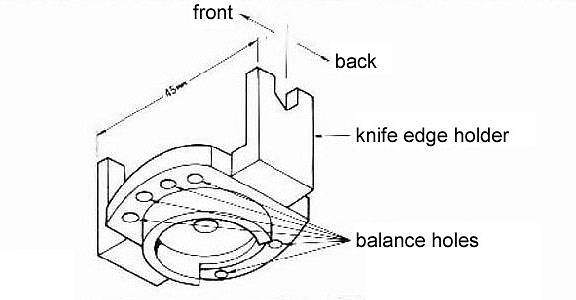

Machined at both ends of the arm pivot member are four knife edges, two on each end 180° opposed to each other and which are hand finished to rigid tolerances so that all four knife edges are in perfect alignment. The arm pivot member is borne by the two outermost and downward facing knife edges resting on the knife edge holders. The arm pivot member is restrained from lateral movement by side plates attached to the outside surface of the knife edge holders and perpendicular movement is constrained by two knife edge restraints contacting the two upward facing knife edges.

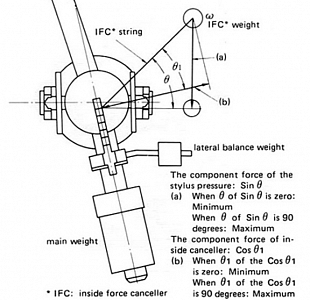

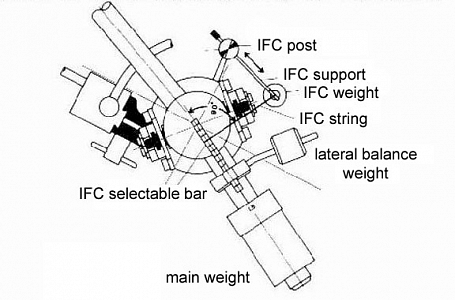

Automatic tracking pressure compensation

The automatic tracking pressure device gradual wand minutely increases stylus pressure as the arm approaches the inner grooves of the record. This prevents the stylus from “floating” within the innermost grooves and allows the cartridge to reproduce high frequency information accurately and without increasing distortion products or degrading stereo separation.

Bearing assembly base plate

To assure absolute balance, the Double Knife Edge bearing assembly base plate is statically balanced. This procedure is particularly important since the complete tonearm rests and depends on the horizontal integrity of this base plate. When the lateral balance of the tonearm is adjusted with the lateral balance adjuster and as a result of the static balancing of the bearing assembly base plate, three axes are in perfect balance. Even if the turntable is not leveled correctly, the tonearm will function as if it were level.

Inside force canceller

Since all pivot tonearms track records in an arc, it is necessary to position the stylus a small distance from the spindle (overhang) so that the least amount of tracking error is present at all points of the record. Because of this overhang, a systematic unbalance is created past the midpoint of the arc. This unbalance causes the stylus to be forced inward on the inner grooves and this force increases as the stylus approaches the innermost grooves of the record. This inside force must be cancelled otherwise the stylus will exert undue pressure on the inner wall of the groove causing increased wear and damage to the delicate record grooves as well as degrading inner groove reproduction.

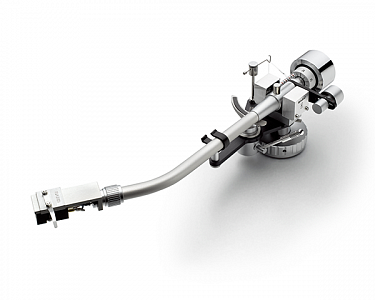

The result of the development of the described solutions was the 407 series of SAEC tonearms, significantly decreasing double knife edges with improving the knife edge restraints mechanism.

The manufacturing precision of WE-407 was increased; SAEC was able to deliver a precision level of more than ±0,05mm. Also, owing to high-precision manufacturing technologies and state of the art craftsmanship work, SAEC has succeeded with downsizing the double knife edge and thus achieved flexibility in regard to light, high-compliance cartridges.

By adding the mechanical equalizer which optimally filters low pass resonance and by using the newly developed mechanical damping construction, SAEC has succeeded at decreasing Q0 without sacrificing critical functions.

A tonearm has been produced that performs optimally with all cartridges, whether low mass or high, lower compliance or high compliance type — and in a compact design.

The solutions applied to the 407 tonearm were so successful that the arm is still in production today (current model WE-4700).

We at fonolab provide full service for the 407 series and also build original designs based on a bearing assembly.

You will teleport into the golden age of audio while retaining all the modern conveniences of fine-tuning.

We will be happy to provide any advice on setting up and repairing your SAEC tonearm.

We are also proud to present our modern take on the classic WE-407 – the fonolab WE-404/ST medium mass straight tonearm.